Withdrawal of the aluminum nor processing of aluminum.

Please leave Save of aluminum

pipe.

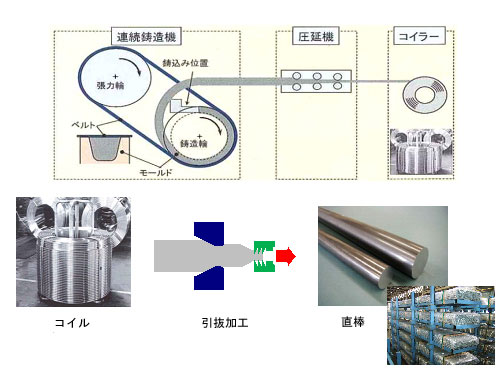

Continuously casted and rolled bars

What is continuously casted and rolled bar?

Productivity from this kind of bar is higher than that of extruded bars since the production from casting to rolling is a continuous process.

By combining process with highly precise technology, we can produce bars with outstanding cost performance and high precision.

Difference between continuously casted and rolled material and extruded material

| Comparison | Continuously casted and rolled material | Extruded material |

|---|---|---|

| Chemical composition | Turned into a specific component in a heat-treating furnace. | |

| Productivity | The process from molten metal to rough wire rods is continuous and can achieve very good productivity thanks to the high processing speed. Additional heat treatment is not required. | Heat treatment is required since the process flow stops at each step. Also, productivity is poor due to the very slow extrusion process. |

| Product yield | Yield loss occurs only at the very beginning and end of the production line and high production yield is achieved. | Production has to pause at each station and yield loss occurs at each. |

| Cross-sectional shape | Mainly for round tubes and it is difficult to produce irregular-shaped tubes. | Various kinds of cross-sectional shapes can be produced by changing the die. |

| Size | Bars between 16mm and 24mm can be produced. Please contact us for the other sizes. | Productivity worsens as batches get smaller, but tubes in various sizes can be produced. |

| Metal structure | Production from molten metal to end-product is continuous and it is easy to control the line and keep it even. Because the structure rapidly solidifies, it is more delicate than extruded material. | Friction between the container and the beginning and end of the bilet is different. Friction varies among production stages and causes unevenness to the metal structure and strength. |

| Metal flow | Rolling is wrought from three directions which differs from regular continuous casting. This gives rolling an advantage. Also, the metal flow is even without any deadzones because of the continuous process. | Flow is not even from the beginning till the end of extrusion and deadzones can easily form. |

Examples of applying products.

・Automotive AT spool valve

・OA flange

・Various shaft